The global market for Heavy Duty Electrical Wire Connectors is poised for significant growth in the coming years, driven by increasing demand across various sectors such as industrial, automotive, and renewable energy. According to a recent industry report, the market is expected to reach approximately $XX billion by 2025, with a compound annual growth rate (CAGR) of XX%. This surge is largely attributed to the rising adoption of advanced technologies and the growing need for reliable electrical connections in harsh environments. Leading manufacturers are expanding their product offerings to address the challenges posed by extreme conditions and high-performance requirements, thus enhancing the overall safety and efficiency of electrical systems. As we delve deeper into this topic, we will explore key players in the market and provide examples of innovative connector solutions that are shaping the future of heavy-duty applications.

As the industry moves towards 2025, several emerging trends in heavy-duty electrical wire connectors are set to revolutionize manufacturing and application processes. One notable trend is the increasing focus on eco-friendly materials and sustainable practices. Manufacturers are investing in biodegradable polymers and recyclable metals, which not only reduce environmental impact but also appeal to a growing demographic of eco-conscious consumers. This shift towards sustainability is becoming a key differentiator in the competitive market of heavy-duty connectors.

Another significant trend is the advancement in technology, particularly the integration of smart features in connectors. This includes the use of IoT (Internet of Things) capabilities, allowing for real-time monitoring of electrical connections. Such innovations enhance safety and efficiency, minimizing downtime caused by connection issues. Additionally, the rise of automation in manufacturing processes further improves the reliability and precision of connectors, catering to industries requiring high-performance solutions. As these trends evolve, they will undoubtedly shape the future landscape of heavy-duty electrical wire connectors, making them not only more efficient but also more aligned with the technological and environmental demands of modern applications.

| Manufacturer Type | Annual Revenue (USD Billion) | Market Share (%) | Emerging Trend | R&D Investment (USD Million) |

|---|---|---|---|---|

| Connector Manufacturer A | 2.5 | 15 | Sustainable Materials | 150 |

| Connector Manufacturer B | 3.0 | 20 | Smart Connectors | 200 |

| Connector Manufacturer C | 1.8 | 10 | Automated Manufacturing | 100 |

| Connector Manufacturer D | 4.2 | 25 | IoT Integration | 250 |

| Connector Manufacturer E | 3.5 | 18 | High Voltage Solutions | 180 |

The heavy-duty electrical connector market is poised for significant growth as we approach 2025, with key players striving to meet the increasing demand catalyzed by advancements in technology and the burgeoning electric vehicle (EV) sector. According to recent reports, the Asia Pacific connector market alone has surpassed USD 39.5 billion in 2024 and is expected to grow at a CAGR of 4.1% until 2034. This growth is driven by the rising need for reliable and efficient connectors that can support both industrial applications and the expanding EV charging infrastructure.

Additionally, the industrial connector market is projected to experience consistent growth, registering a value of over USD 8.7 billion in 2024, with an anticipated CAGR of 2.8% through 2034. As manufacturers innovate and enhance product designs, there's an increasing emphasis on durability and performance in heavy-duty electrical wire connectors. This focus is critical not only for maintaining system stability but also for ensuring longevity in applications ranging from automotive to renewable energy sectors, where effective power management is essential.

Thus, industry leaders are positioning themselves strategically to capture a larger share of the market amidst these dynamic developments.

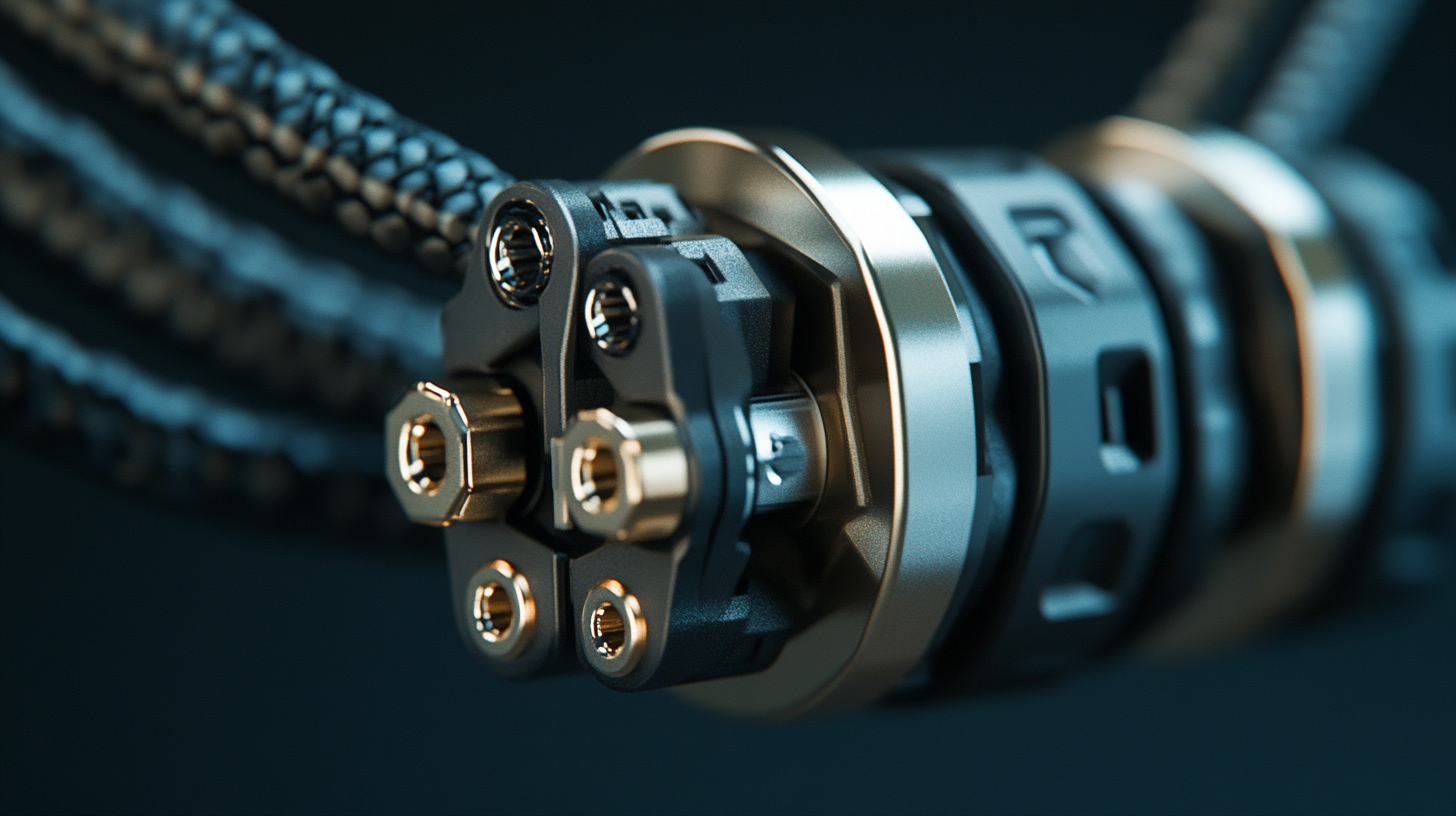

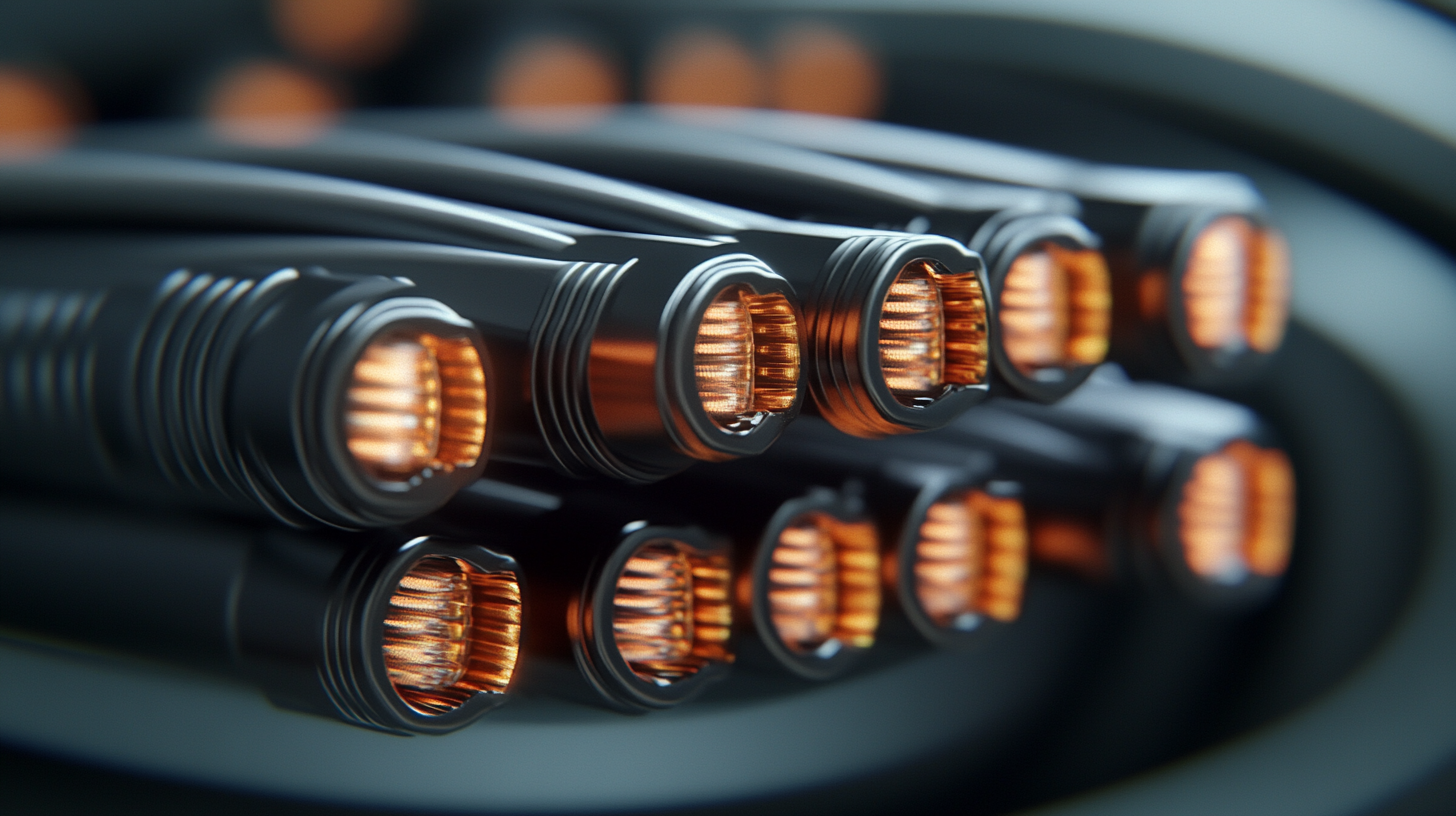

As the demand for reliable electrical connections grows in various industries, technological innovations are playing a pivotal role in reshaping the future of heavy-duty electrical wire connectors. Advanced materials, such as high-conductivity copper alloys and robust polymers, are being utilized to enhance durability and performance. These materials not only improve electrical efficiency but also ensure connectors can withstand harsh environmental conditions, making them suitable for applications in automotive, aerospace, and industrial sectors.

Moreover, the development of smart connectors is revolutionizing the industry. These connectors are embedded with sensors that monitor connection integrity in real time, providing invaluable data to prevent failures before they occur. With wireless communication capabilities, they allow for remote diagnostics and maintenance, reducing downtime and boosting productivity. As technological advancements continue to emerge, the heavy-duty electrical wire connector market is expected to evolve, meeting the increasing demands for safety, efficiency, and sustainability.

As the global demand for heavy-duty electrical wire connectors continues to rise, so does the focus on sustainability practices among leading manufacturers. According to a recent market report by Grand View Research, the heavy-duty connectors market is projected to reach $9.25 billion by 2025, with a Compound Annual Growth Rate (CAGR) of 5.8%. This growth is accompanied by a significant shift towards environmentally responsible manufacturing processes. Companies are now prioritizing sustainable materials and production techniques, reflecting a broader industry movement towards minimizing environmental impact.

Many top manufacturers have adopted circular economy principles, integrating recycled materials into their connector designs while reducing waste throughout their operations. For instance, a Nielsen report indicated that 66% of consumers are willing to pay more for sustainable brands, which encourages manufacturers to invest in greener technologies. Additionally, initiatives such as energy-efficient manufacturing and reduced carbon footprints are becoming standard practices among leaders in the industry, ensuring that they not only meet regulatory requirements but also respond to the increasing consumer demand for environmental stewardship.

By 2025, these sustainability practices are expected to become a key differentiator in the heavy-duty electrical wire connector market, positioning companies as responsible leaders in an evolving landscape.

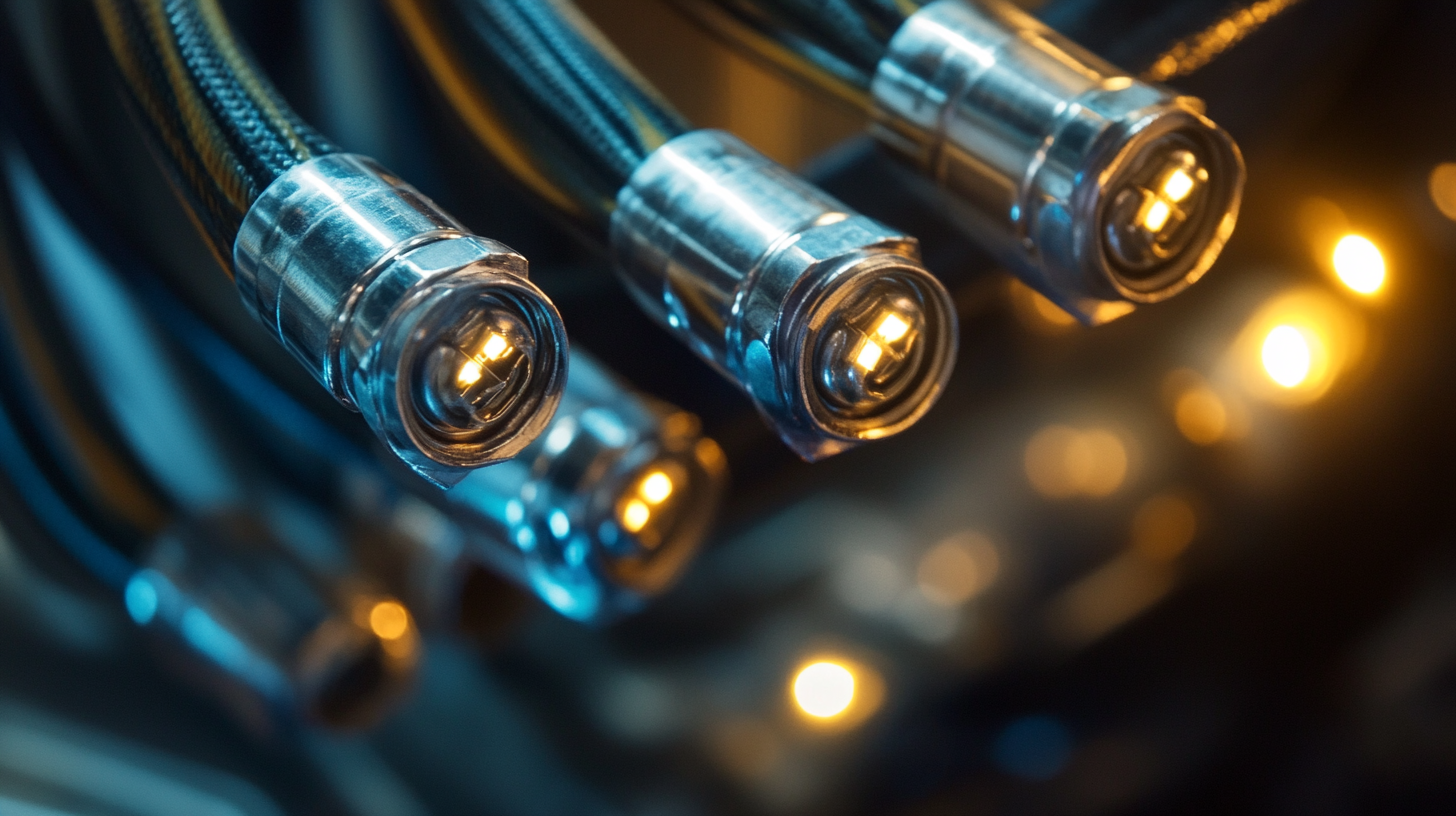

The market for heavy-duty electrical wire connectors is currently navigating a landscape filled with both challenges and opportunities. As technology continues to evolve, particularly in sectors like electric vehicles (EVs), the standardization of charging connectors is both necessary and complex. Major regional markets such as North America and Japan have established their own standards, which pose challenges for manufacturers looking to cater to global demands. The rapidly changing technology landscape requires manufacturers to be agile, ensuring their products meet safety, performance, and compatibility standards across different markets.

One of the notable opportunities lies in the advancements surrounding EV charging systems. As the market for electric vehicles expands, so does the need for robust and reliable heavy-duty electrical connectors. Manufacturers have a chance to innovate and develop connectors that not only fulfill regulatory requirements but also enhance user experience by providing faster and more efficient charging solutions. This shift towards electrification presents a ripe environment for investment and product development, allowing manufacturers to position themselves as leaders in a redefined industry landscape.