In recent years, the global demand for high-performance electrical components has surged, positioning China as a leading manufacturer of Heavy Duty Electrical Contacts. This blog delves into the critical aspects that set Chinese-made heavy duty electrical contacts apart from their competitors in terms of quality assurance, innovation, and technological advancements. As industries worldwide increasingly rely on robust electrical solutions to power their operations, understanding the stringent standards and testing protocols that govern the production of these contacts becomes essential.

We will explore how these heavy duty electrical contacts are designed to withstand extreme conditions, ensuring reliability and safety in diverse applications. Join us as we uncover the factors contributing to this impressive sales surge and what it means for manufacturers and consumers alike.

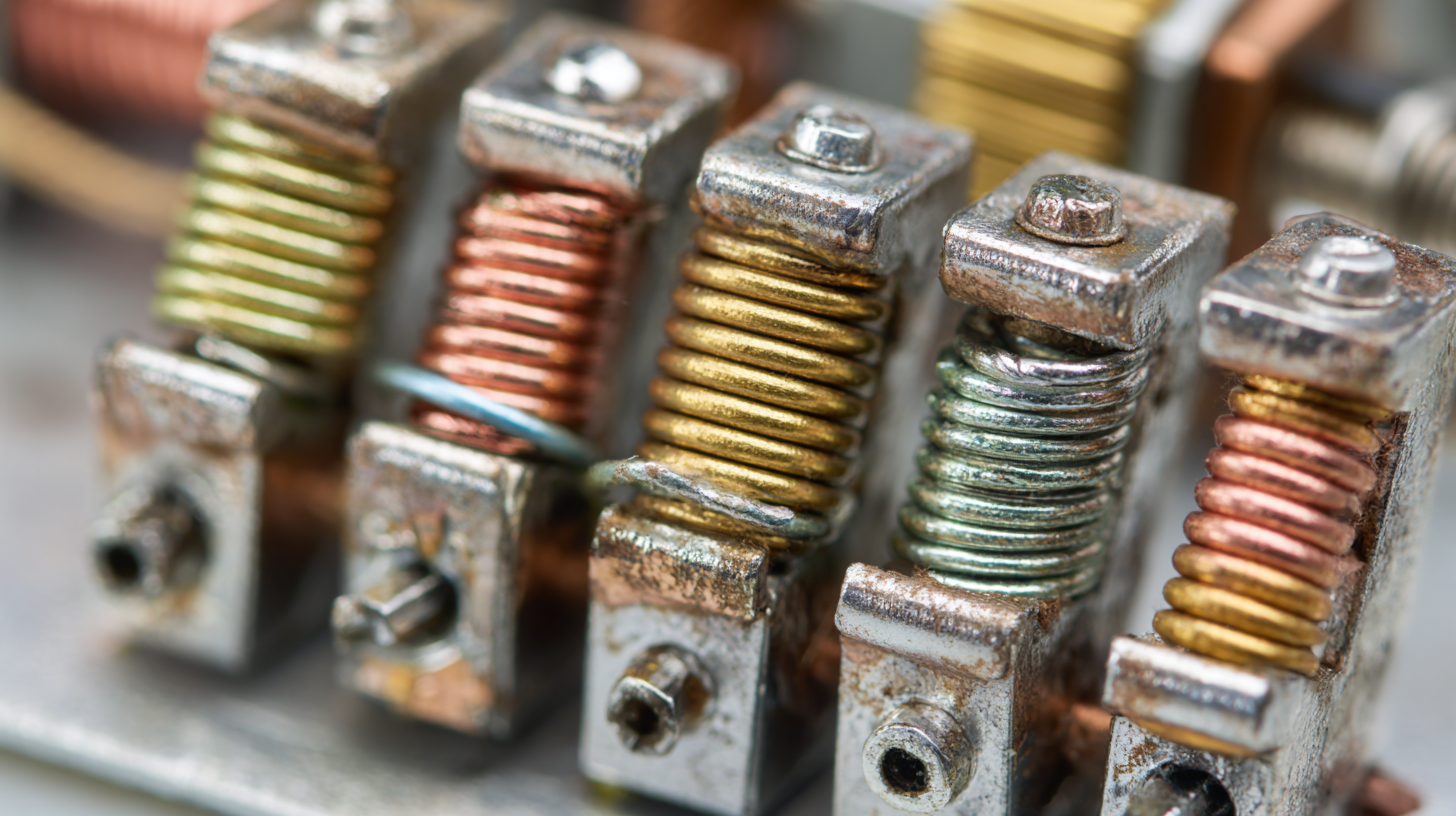

Heavy duty electrical contacts are vital in a variety of industrial applications, providing robust connectivity for high-voltage and high-current environments. These contacts are constructed to withstand extreme conditions, ensuring durability and reliability. The materials used, typically copper or silver, are carefully chosen for their excellent conductivity and resistance to wear. Additionally, features such as corrosion resistance and mechanical strength are essential for long-term performance in demanding situations.

When selecting heavy duty electrical contacts, consider the following tips: First, evaluate the environmental conditions where the contacts will be used. This includes humidity, temperature fluctuations, and exposure to chemicals, all of which can affect contact longevity. Second, ensure that the specifications meet or exceed the operational requirements of your application. This involves checking current ratings, voltage ratings, and compatibility with other components in the system. Finally, prioritize manufacturers that adhere to quality assurance standards, as this will significantly influence the reliability of the contacts over time.

The demand for high-quality electrical contacts manufactured in China has been experiencing a remarkable surge, particularly in various industrial applications. As industries evolve, the necessity for durable and efficient electrical connections has risen. Best quality electrical contacts serve critical roles in sectors such as automotive, aerospace, renewable energy, and industrial automation. These connections ensure seamless power transmission and enhance overall system reliability, which is paramount in an era focused on innovation and efficiency.

In particular, the heavy-duty electrical contacts are integral to the development of electric vehicles and renewable energy systems, where they handle significant current loads and withstand harsh conditions. Such robust contacts not only improve the longevity of devices but also reduce maintenance costs, solidifying their value across industries. As manufacturers continue to prioritize quality assurance in their production processes, the global market for these components is expected to expand further, driven by technological advancements and increased demand in diverse applications. This growth reflects the ongoing commitment to delivering superior products that meet rigorous industry standards.

In the rapidly evolving world of electrical contacts, the demand for heavy-duty electrical contacts is surging, outpacing standard contacts in various applications, particularly in the burgeoning electric vehicle market. According to recent market analyses, the DC contactor market for electric locomotives is projected to reach a value of approximately $113.7 million in 2023, with an anticipated compound annual growth rate (CAGR) of 7.4% from 2024 to 2032. This growth is driven by technological advancements in contactor design, especially in developing countries, which enhance the performance and reliability of heavy-duty electrical contacts.

The comparative analysis of heavy-duty electrical contacts versus standard contacts reveals significant advantages in terms of durability, efficiency, and safety. Heavy-duty contacts are specifically engineered to handle higher loads and withstand extreme conditions, making them indispensable in critical applications such as electric vehicles and industrial machinery. As the market continues to expand, manufacturers are prioritizing quality assurance and innovative design to meet the increasing demands, particularly from sectors that require robust and reliable solutions. This trend underscores the importance of investing in higher-quality contacts to ensure long-term operational effectiveness and safety in electrical systems.

When considering heavy duty electrical contacts, quality and reliability are paramount. Chinese manufacturers have established themselves as leaders in the industry, offering numerous advantages that are hard to overlook. One of the primary benefits of choosing Chinese manufacturers is their advanced production technologies. With significant investments in automation and quality control, these companies ensure that their products meet stringent international standards, providing customers with peace of mind regarding performance and safety.

Moreover, the cost-effectiveness of sourcing heavy duty electrical contacts from China cannot be ignored. Manufacturers leverage economies of scale and efficient supply chains, resulting in competitive pricing without compromising on quality. This not only allows businesses to reduce operational costs but also enables them to invest savings into other critical areas, fostering growth and innovation. As global demand for high-quality electrical contacts continues to rise, partnering with reputable Chinese manufacturers presents a strategic advantage in meeting both current and future market needs.

In recent years, the global demand for heavy-duty electrical contacts has seen an unprecedented surge, driven primarily by innovations in electrical contact technology. Manufacturers in China are at the forefront of this evolution, introducing advanced materials and designs that enhance the performance and longevity of electrical contacts. These innovations include the use of newly developed alloys that resist corrosion and wear, as well as improved manufacturing processes that ensure tighter tolerances and higher quality outputs. As a result, the reliability of electrical connections has significantly improved, meeting the rigorous demands of various industries.

The impact of these technological advancements on the market is profound. With enhanced product quality, Chinese manufacturers can compete more effectively on a global scale, capturing market share from traditional leaders. This shift has prompted other regions to innovate and refine their own production techniques to maintain competitiveness. Furthermore, the increased focus on quality assurance has led to greater consumer confidence in products made in China, breaking down longstanding perceptions about manufacturing quality. As the market continues to evolve, the synergy between innovation and quality assurance will play a critical role in shaping the future of heavy-duty electrical contacts.

| Year | Sales Volume (in Million Units) | Market Growth (%) | Export Value (in Billion USD) | Innovation Index (1-10) |

|---|---|---|---|---|

| 2020 | 150 | 5 | 1.2 | 7 |

| 2021 | 180 | 10 | 1.5 | 8 |

| 2022 | 210 | 12 | 1.9 | 9 |

| 2023 | 250 | 15 | 2.3 | 10 |